Sanitary Pumps Sealing-Packing

The sealing quality is the most important factor to consider during the selection of pumps. There are two forms of pump sealing: packing, mechanical sealing and rubber oil sealing. In this article, we’ll focus on the pump packing.

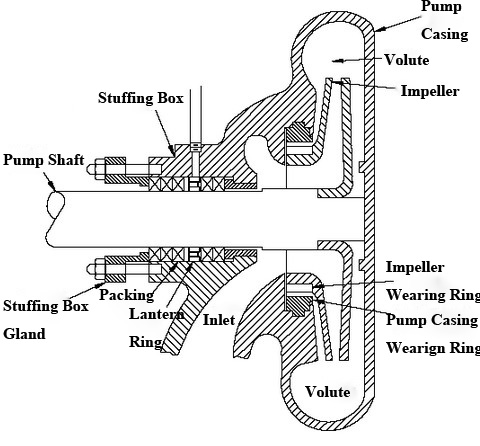

Packing is located in the stuffing box at the dry end of the pump (as shown in the picture below). It serves to control the fluid leakage along the pump shaft and prevent air from entering along the shaft when the pump is in a suction lift condition.

Technical Requirements

To control leakage, the packing material must be flexible so that it can be properly tightened around the shaft. It must also be kept under enough pressure and run tight against the rotating shaft. During the pump operation, there must be heat generated due to the friction between the rotating shaft and the stationary packing. Therefore, the selected packing material must be able to withstand the friction without operation failure or undue damage to the shaft or shaft sleeve. It must also be able to transfer the heat to the stuffing box walls without damaging itself.

To reduce the generated heat, certain degree of leakage through the packing may be necessary. This forms one of the disadvantages of packing sealing because the leakage amount is difficult to control. In addition, to reduce the friction, an external lubricant through the lantern ring should be adopted. Grease, oil and water are all used as external lubricants. When water is used, it is referred to as seal water.

Due to the constant consumption of lubricant, the packing materials would reduce in tightness and decline in sealing ability. This will require that the packing materials be replaced periodically.

Prev: DN and NPS Comparison Next: How to Replace a Packing (1)