4'' Sanitary Shutoff And Divert Valves AV-5SS AISI-316L

Application

When stopping or diverting flow in a process system, the AV-5SS series single seat valve line provides both a flexible and reliable solution. These valves are pneumatically or manually operated, and offered in a wide variety of body configurations.

Materials

Materials: AISI-316L

Size: 4''

Seat materials: EPDM (Std), other seats available upon request.

Elastomers: FPM (Std), EPDM (Opt) -- all seals complying with FDA21CFR177.2600

Standard Design

The self draining machined and polished valve bodies are made from acid resistant stainless steel. Their round shape offers minimum resistance to flow. The valve body and pneumatic actuator are connected by clamps enabling easy and quick assembly and disassembly. The design ensures easy cleaning of the valve plug. The configuration of valve can be changed from normally closed to normally open or vice-versa by just inverting the actuator. All seats and seals are made from FDA approved materials.

Actuators

Normally Closed (NC) - Air to open and spring to close;

Normally Open (NO) - Air to close and spring to open;

Air to Air (AA) - Air to open air to close;

Manual version - Opened or closed manually by rotating the handle.

Technical Specification

- Size available: DN25-1" to DN100-4"

- Max. working pressure: 147psi (10bar)

- Control air pressure: 70 ~ 116bar (5 ~ 8bar)

- Working temperature range: EPDM: 14 ~ 248°F (-10 ~ 120°C)

- Sterilization temperature: 302°F (150°C, Max. 20 min)

- Pneumatic connection: G1/8" (BSP)

- End connections: butt-welded, sanitary clamp, threaded, flange, DIN, SMS, RJT, IDF or others upon request.

- Finish: <32Ra (<0.8µm); Other finishes available upon request

Technical Parameters |

|||

|

Steel material |

Product wetted steel parts |

AISI 316L |

Provided with material inspection report |

|

Other steel parts |

AISI 304 |

||

|

Seal material |

Standard |

EPDM |

All seal materials comply with FDA 21CFR117.2600 |

|

Options |

FPM, Silicone, NBR |

||

|

Pressure |

Working pressure |

0 ~ 147psi (0 ~ 10bar) |

|

|

Supply pressure for air actuator |

5 ~ 8bar (70 ~ 116psi) |

||

|

Temperature |

Working temperature |

EPDM: 14 ~ 248°F (-10 ~ 120°C) |

|

|

Surface treatment |

Inside surface treatment |

Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

|

|

Outside surface treatment |

Sand blast or mirror |

||

|

Connection |

End connections: butt-welded, sanitary clamp, threaded, flange, DIN, SMS, RJT, IDF or others upon request. |

||

|

Pneumatic head |

Normally Closed (NC) - Air to open and spring to close; |

||

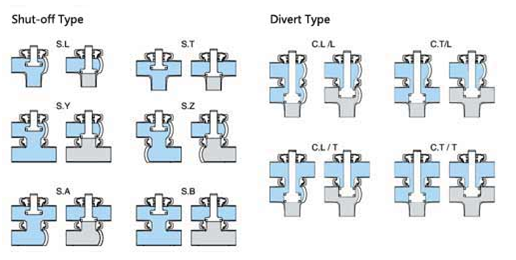

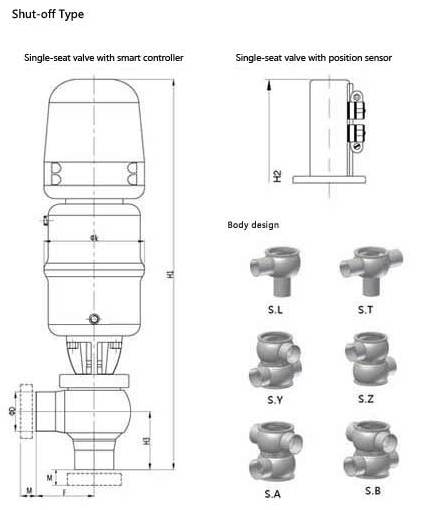

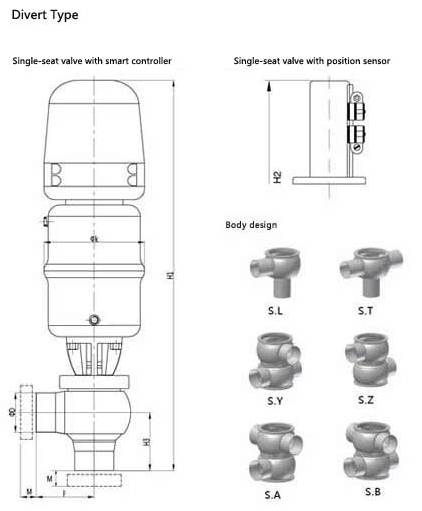

Variety Of Body Configurations

Dimensions (mm)

|

DN |

D |

K |

F |

H1 |

H2 |

H3 |

M (Clamp) |

|

25 |

29×1.5 |

91 |

55 |

402 |

344 |

55 |

21.5 |

|

Inch |

|

||||||

|

1.0" |

25.4×1.65 |

91 |

55 |

402 |

344 |

55 |

12.7 |

Dimensions (mm)

|

DN |

D |

K |

F |

H |

H1 |

H2 |

H3 |

M (Clamp) |

||||||

|

25 |

29×1.5 |

91 |

65 |

452.3 |

394.3 |

50.3 |

55 |

21.5 |

||||||

|

32 |

35×1.5 |

91 |

65 |

529.5 |

471.5 |

66 |

62.5 |

21.5 |

||||||

|

40 |

41×1.5 |

91 |

65 |

529.5 |

471.5 |

66 |

62.5 |

21.5 |

||||||

|

50 |

53×1.5 |

130 |

75 |

585.3 |

527.3 |

78.6 |

75 |

21.5 |

||||||

|

65 |

70×2.0 |

130 |

90 |

618.7 |

560.7 |

94.3 |

90 |

28 |

||||||

|

80 |

85×2.0 |

195 |

105 |

739.5 |

581.5 |

110.3 |

105 |

28 |

||||||

|

100 |

104×2.0 |

195 |

120 |

792 |

724 |

128.3 |

120 |

28 |

||||||

|

Inch |

|

|||||||||||||

|

1.0" |

25.4×1.65 |

91 |

65 |

452.3 |

394.3 |

50.5 |

55 |

12.7 |

||||||

|

1.5" |

38.1×1.65 |

91 |

65 |

529.5 |

471.5 |

66 |

62.5 |

12.7 |

||||||

|

2.0" |

50.8×1.65 |

130 |

75 |

585.3 |

527.3 |

78.6 |

75 |

12.7 |

||||||

|

2.5" |

63.5×1.65 |

130 |

85 |

613 |

555 |

90.5 |

85 |

12.7 |

||||||

|

3.0" |

76.2×1.65 |

195 |

95 |

719.2 |

661.2 |

103 |

95 |

12.7 |

||||||

|

4.0" |

101.6×2.11 |

195 |

120 |

792 |

724 |

128.3 |

120 |

15.8 |

||||||