4'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L

Application

Sanitary check valve, also known as "non-return valve", is designed for use in process piping installations to prevent reverse flow. AV-3F series is a kind of 3-piece flanged spring check valve.

Materials

Materials: AISI-316L

Size: 4"

O ring and gasket: EPDM, comply with FDA21CFR177.2600

Options

- O ring and gaskets can be Silicone or Viton, all complying with FDA 21CFR177.2600.

- Connection ends: butt-welded, sanitary clamp, threaded, flanged, union or others upon request.

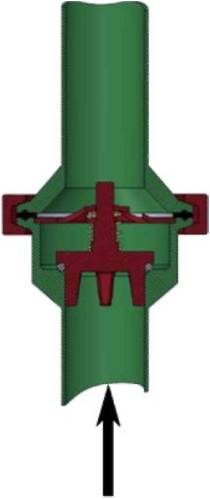

Working Principle

A check valve opens when the pressure below the valve plug exceeds the pressure above the valve plug and the spring force. The valve close when pressure equalization has been achieved.

Design Features

The stainless steel valve body ensures nonporous, smooth surfaces and dimensionally stable construction. The valve body is in two parts, assembled by means of a standard clamp and sealed with a standard gasket. The self draining design of the lower valve body enables flushing of the product. Ribbed construction of the stainless steel disc resists heavy pressure hammer, minimize the resistance to flow and also serves as a guide to the valve plug. All seats and seals are made from FDA approved materials.

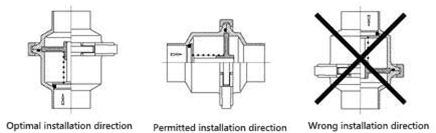

Above picture shows the default configuration. Horizontal positions are also permitted. The four guide legs of the valve ensure good alignment.

Technical Specification

- Max. pressure: 10bar (145psi)

- Opening pressure: 0.3bar (DN25); 0.2bar (DN32 ~ 40); 0.1bar (DN50 ~ 100). The opening pressure can be set as customers require.

- Working temperature: 14 ~ 248°F (-10 ~ 120°C ), EPDM

Technical Parameters |

|||

|

Steel material |

Product wetted parts |

AISI 316L / 304L |

Provided with material inspection report |

|

Other steel parts |

AISI 304 |

||

|

Sealing material |

Standard |

EPDM |

All seal materials comply with the FDA 21CFR117.2600 |

|

Options |

VMQ / Viton |

||

|

Pressure |

Working pressure |

≤10bar (145 PSI) |

|

|

Temperature |

Working temperature |

EPDM: 14 ~ 248°F (-10 ~ 120°C) |

|

|

Sterilization temperature |

150°C (Max. 20 min) |

||

|

Surface treatment |

Inside surface treatment |

Ra 16 ~ 32 µin (0.4 ~ 0.8µm) |

|

|

Outside surface treatment |

Ra 32 ~ 64µin ( 0.8 ~ 1.6µm) |

||

|

Connection |

The welding diameter |

Welding end: |

|

|

End connections: butt-welded, sanitary clamp, male and female threaded, flanged, etc. |

|||

AV-3F of Other Sizes

1/2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

1'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

1 1/2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

2 1/2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

3'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

4'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-304

1/2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L

1'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L

1 1/2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L

2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L

2 1/2'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L

3'' Sanitary 3 Piece Flange Check Valves AV-3F AISI-316L