1/2'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L

Application

AV-4P series is pneumatic sanitary diaphragm valve, which is widely used in food, beverage, dairy, brewing, pharmaceutical industries, etc. The valve is excellent for flow control as well as for open/close duties.

Materials

Materials: AISI-316L

Size: 1/2''

Diaphragm: EPDM + PTFE

The seal materials comply with FDA177.2600 standard. Using proprietary technology, the diaphragm uses a combination of EPDM and PTFE, which is secured using SS bolts. The sealing part where contact with the medium is of PTFE material, it has good cold resistance -13°F (-25°C), excellent heat-resistance 482°F (+250°C), tolerance to most chemicals, and excellent abrasion resistance to medium flow.

Standard Design

- Standards: DIN, 3A, SMS, ISO / IDF, BS / RJT, ASME / BPE.

- The parts mainly include: a pneumatic head, diaphragm and valve body which are assembled together with bolts and nuts. The body can be two ways or three ways.

- End connections: butt-welded, sanitary clamp, or others upon request

- Body type: T-type tee, U type tee, Mini type, tank bottom type, etc.

Technical Specification

- Size available: 1/4", 1/2", 3/8", 3/4", 1", 1 1/2", 2", 2 1/2", 3"

- Max. working pressure: 147psi (10bar)

- Temperature range: 14 ~ 248°F (-10 ~ 120°C), EPDM

- End connections: butt-welded, sanitary clamp, T-type tee, U type tee, Mini type and tank bottom type, etc.

- Inside polishing: Ra 16 ~ 32µin (0.4 ~ 0.8µm)

- Diaphragm available: EPDM+PTFE / EPDM / Silicon / FPM (Viton)

Technical Parameters |

|||

|

Steel material |

Product wetted parts |

AISI 316L / 304 forged |

Provided with material inspection report |

|

Other steel parts |

AISI 304 |

||

|

Seal material |

Standard |

EPDM+PTFE |

All seal materials comply with FDA 21CFR117.2600 |

|

Options |

VMQ |

||

|

Pressure |

Working pressure |

0 ~ 10bar (0 ~ 145psi) |

|

|

Control air pressure |

5 ~ 8bar (70 ~ 120psi) |

||

|

Temperature |

Working temperature |

EPDM: 14 ~ 248°F (-10 ~ 120°C) |

|

|

Sterilization temperature |

302°F (150°C, Max. 20 min) |

||

|

Surface treatment |

Inside surface treatment |

Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

|

|

Outside surface treatment |

Ra 32 ~ 63µin (0.8 ~ 1.6µm) |

||

|

Connection |

The welding diameter |

Welding ends: |

|

|

End connections: butt-welded, sanitary clamp, T-type, U-type or others upon request. |

|||

|

Pneumatic control |

Normally Closed (NC) - Air to open and spring to close; |

||

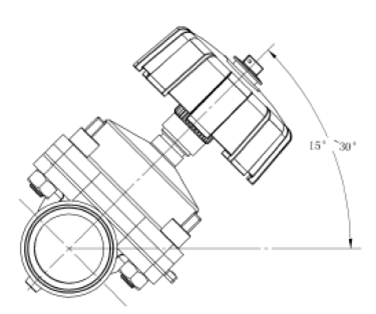

Optimal Installation Angle

|

Due to the structure feature, 15° ~ 30° is the optimal angle for installation,which makes complete drainage after cleaning and keeps no residue. |

|

AV-4P of Other Sizes

1/4'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L

3/8'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L

3/4'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L

1'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L

1 1/2'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L

2'' Sanitary Pneumatic Diaphragm Valves AV-4P AISI-316L